Gloria, the Earrings

I have often heard it said that women do not like matching jewelry; I don’t understand that sentiment especially if the jewelry is made from unusual materials like the grossular green garnet beads used for the bracelet. So when I completed Gloria the bracelet, I knew I would be making earrings and a ring, not quite “matchy matchy” but enough, to complete the look.

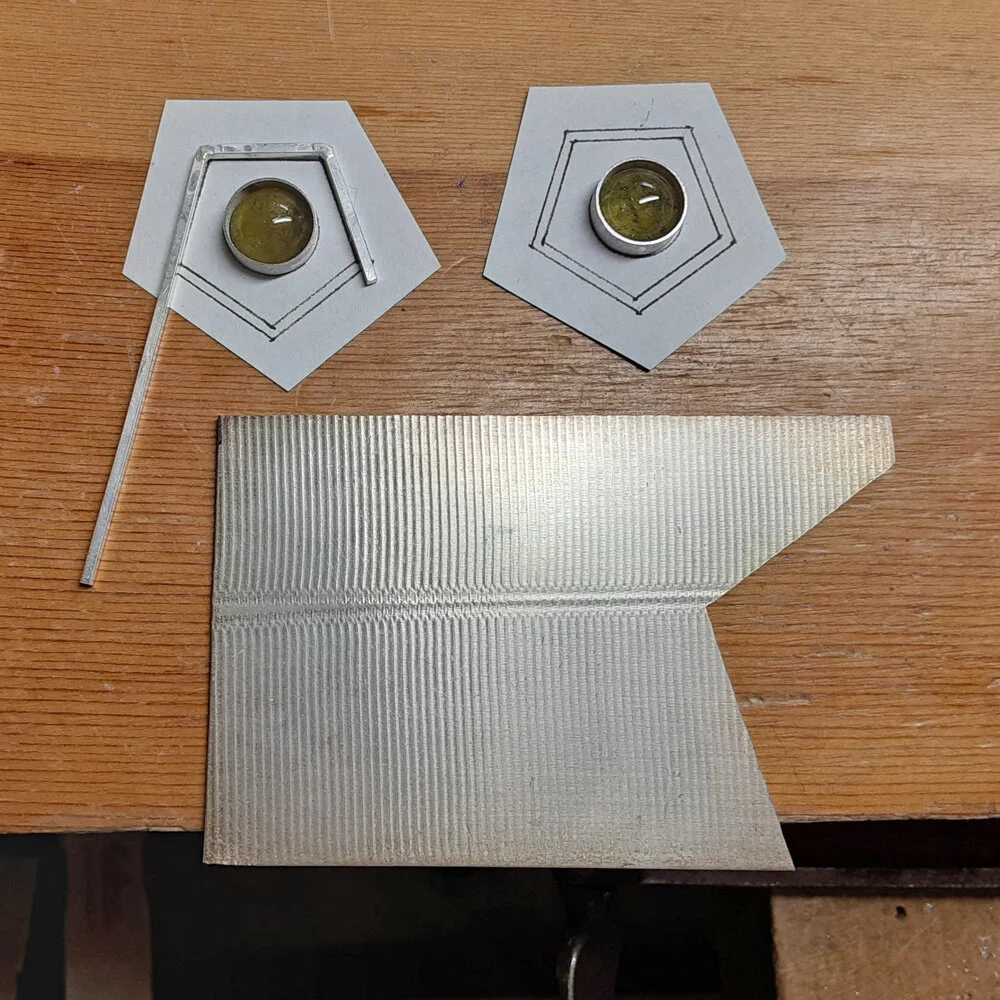

Since the bracelet clasp is a pentagon, I used that shape for the earrings. Unlike the clasp, though, I decided that the earrings needed a border which I created from square wire. And I had enough of the roller-printed sterling that I used for the bracelet clasp to use in the earrings. Below is a picture of the work-in-progress.

In the picture, you see the pattern I drafted for the earrings, necessary for the shaping of the square wire border and to ascertain how much of the sheet to use for each earring. You also note that I’ve made the bezels for the green garnets. BTW, the stones were cut from a bead left over from the bracelet — that way I know I’ll have the same color for the bracelet, earrings and, eventually, ring(s). You also see from the picture the roller-printed sterling — the material I used for the imprinting was a piece of grosgrain ribbon.

Once the square wire borders are made, I can then solder them to the sterling sheet. Below is a picture of the work-in-progress.

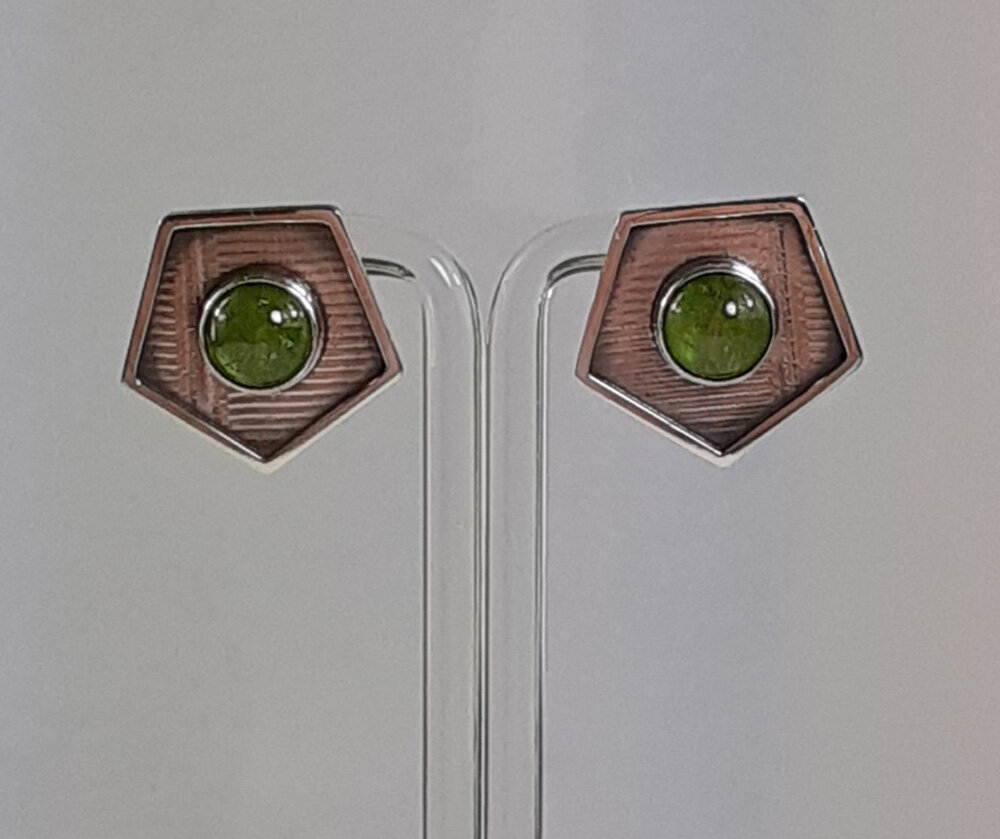

In the above picture, you see that I’ve not only soldered the square wire border to the printed sheet, but I’ve also trimmed off the excess of the earring on the left. Next to that earring is the second awaiting trimmiong after having been soldered — you can barely make out the solder ghosts on the outside of the square wire border. Once these steps have been completed (and you now know that I like to make the earrings simultaneously rather than one at a time), I will solder one the bezels. Below is a picture of the earrings, the stones having been set after initial polish.

Initial polish means that I polish the back of the earrings, ridding them of fire scale, the bane of silversmiths everywhere. Fire scale is caused by the copper in the stering alloy, and the copper oxidizes in the metal when the piece is soldered. Fire scale is difficult to see prior to polishing, but mush easier to see during the polishing process. I do not polish the roller-printed material as I will oxidize it and then lightly polish it to bring out the oxidizing.

Another thing to note is this: I prefer to make earrings that are mirrors, not exact copies. You will notice that the roller-printing is “mirrored” rather than the same for the earrings.