Jeanne

While I was waiting for an order for beaded wire I wanted for another project, I decided to make a pair of earrings. I believe a woman is not fully dressed until she puts on a pair of earrings whether she’s in jeans or a ballgown. I tend to wear more formal earrings with my jeans like these.

Before I start sketching or just hashing out an idea, I go into my stones’ stash and select some materials with which I want to work. In this case, I decide on kyanite, an interesting blue stone with wonderful silver striations, some small green onyx stones, and aventurine teardrops. In this pair of earrings, I will have opacity in the kyanite, transparency with the green onyx, and translucence with the aventurine. Below is a picture that shows you my idea for these earrings.

I had already made the bezels (settings) for the kyanite; I decided to use ready-made bezel “cups” for the green onyx. The sterling silver balls I had made a while ago, and decided to use them in this pair of earrings. I laid out all the elements on graph paper which would serve me as the pattern, if you will, for the sterling silver bottom that would “house” the elements. Below is the picture I took after soldering the bezels into sterling silver sheet sized for this project.

The next steps include the soldering of the elements to the bottom silver sheet. This proved to be a two-step process, beginning with the orienting and soldering the jump ring and then soldering all the other elements at once. I did change the design a bit by replacing the oval jump ring for a round one. Below is a picture of the soldering work-in-process.

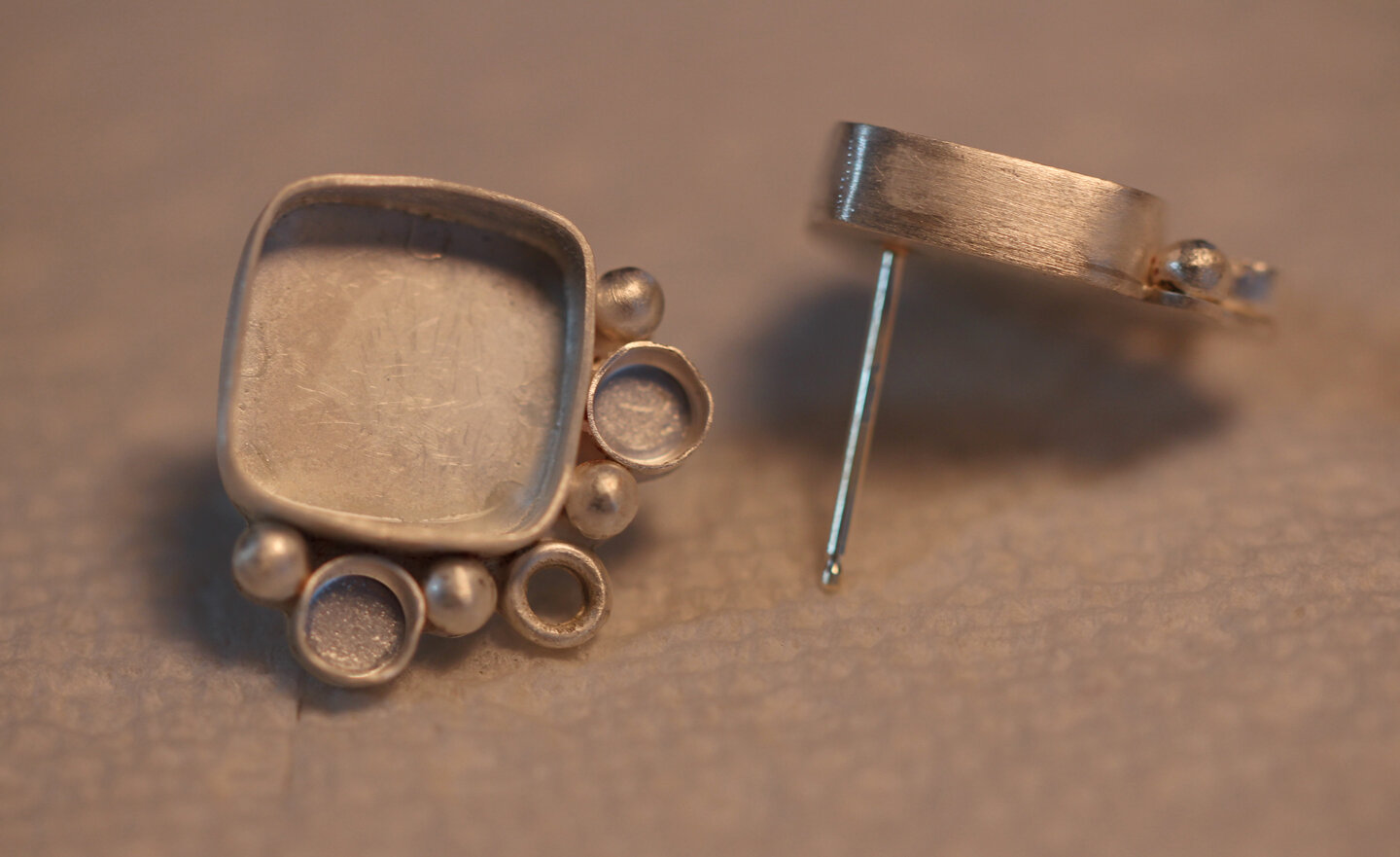

Once I finish the soldering tasks, I trim the excess silver sheet by sawing and filing the edges. When I’m satisfied that the edges are exactly right, I then solder on the posts. Below is a picture of the work-in-progress.

Now for the big clean-up; I spend a lot of time sanding the earrings mostly to rid the pieces of fire scale, the bane of the silversmiths’ work. Fire scale occurs in sterling silver because sterling silver is an alloy that includes copper. The copper ions freely move around the chemical matrix of the alloy especially during soldering. And during soldering, the copper oxidizes turning grey. It takes a novice a long time to see fire scale in sterling while the piece is being worked, but, for sure, during initial polish, fire scale becomes prominent. I like to sand out the fire scale before I start polishing.

After initial polishing, I set the stones and then glue “pearl drop bails” to the aventurine teardrops. The bails and the small bezel cups (those are the settings for the small, green onyx cabochons) are commercially available components, and really make handling small and difficult jobs easier. Below is a picture of the work in progress.

It takes the epoxy glue I use 24 hours to cure fully and so the teardrops remain upright in the tweezers for that long. In the meantime, I can final polish the earrings, and when the teardrops are ready, I join them with oval jump rings that I’ve made to the earrings, and they are done.